The Benefits of Smart SRM

Supplier Discovery & Onboarding

For starters, redesigning global supply chains requires the discovery, onboarding, and qualification of hundreds, if not thousands, of new suppliers. For Procurement teams that are still managing suppliers via scattered data siloes like spreadsheets, emails, and legacy solutions, such an initiative would take countless hours of manual data entry, query handling, and managing inefficient processes.

But with smart SRM technology - such as Kodiak Hub - teams can significantly streamline and automize their supplier onboarding. By utilizing customizable supplier self-registration and self-assessment solutions that integrate directly into the SRM platform, Procurement teams can effortlessly discover more suppliers and collect all the necessary information for qualification. And with a single source of truth that generates automated ratings and insights on risk and compliance, teams can greatly expedite the supplier qualification process and make faster, smarter sourcing decisions.

Read more about how to enhance Supplier Onboarding & Assessments here.

Supplier Risk Management

When it comes to mitigating risk, the importance of a modern SRM solution cannot be understated. Supply chains have no shortage of data that can help monitor and manage risk, but collecting and connect the dots across that information is virtually impossible to do manually.

Smart SRM systems like Kodiak Hub empower Procurement teams with automation, big data enrichment, and AI to leverage vast amounts of data into a 360-degree risk overview with actionable and invaluable insights. Kodiak Hub’s intuitive Supplier Scorecards automatically provide a Country & Macro Risk rating based on a supplier’s location, covering 39 different risk indices such as Human Rights, Labor Rights, Environmental Performance, Business Ethics, Political Stability, Tradeability, and Economic Stability.

Along with contextual risks, our SRM system also gathers third-party risk data such as financial ratings, adverse media monitoring, and screenings for sanctions, blacklists, and PEPs. Combined with streamlined supplier assessment and auditing tools, along with seamless ERP integrations, Procurement teams are empowered with robust ratings covering a wide range of risk areas along with overall scores to easily compare and contrast suppliers.

Automated and holistic risk monitoring is not only essential for redesigning supply chains, but also to ensure ongoing resilience. Cutting-edge SRM technology keeps Procurement teams informed about current risks, including real-time alerts about climate events and other disruptions, and can even make predictions about future risk so teams can take action before problems arise.

Explore how to enhance your Supply Chain Risk & Resilience Monitoring here.

Supplier Performance Management

Supply chains are only as resilient as the performance of the suppliers that they’re composed of. So Procurement will need to enhance their Supplier Performance Management practices to ensure that they’re partnering with the best performing suppliers and continuously driving improvements. Unfortunately, many teams still lack the tools and technology to effectively monitor and manage supplier performance.

But modern SRM systems like Kodiak Hub make it easy for teams to implement leading Supplier Performance Management practices. First, by enabling teams to define the Performance areas that can be measured and align on KPIs with both suppliers and internal stakeholders. Suppliers can then be typified within the platform based on their segment or classification and evaluated with weighted KPIs and customized rating methodologies based on the performance areas and criteria that are most important to different types of suppliers. Supplier performance can then be evaluated using a holistic mix of qualitative and quantitative data, consolidating information from supplier feedback, internal evaluations, and API integrations and transforming that data into detailed Performance ratings.

This mix of hard and soft performance data allows businesses to evaluate their suppliers across a range of Performance areas, including Quality, Delivery, Commercial, Collaboration, Innovation, and Sustainability performance. And besides the easy monitoring of supplier performance, smart SRM systems empower Procurement teams with streamlined solutions for supplier self-assessments and corrective action plans to continuously optimize performance over time.

Whether or not your business is redesigning your global supply chain, smart Supplier Performance Management is crucial for enhancing transparency, quality, reliability, efficiency, and collaboration to build resilience in today’s new landscape of risk.

Read about how to achieve world-class Supplier Performance Management here.

Supplier Collaboration & Innovation

With optimized risk management and SPM, Procurement teams are empowered to identify their best suppliers to enhance collaboration and further enhance resilience. By utilizing streamlined collaboration solutions in a modern SRM platform, Procurement can enhance engagement, communication, knowledge sharing, and trust with key suppliers to drive strategic partnerships that unlock value.

By improving supplier collaboration, businesses can gain better visibility into their supply chains to identify potential risks and work together with their suppliers to mitigate them and develop contingency plans. Collaborative supplier relationships also enable businesses to become a Customer of Choice and have a competitive edge to resolve disruptions together with their partners whenever they occur. Enhancing supplier cooperation and collaboration also facilitates valuable innovation across many areas, whether it be innovating supply chain structures to improve resilience or bringing innovative products to market that drive growth.

The true end goal of Supplier Relationship Management is to establish mutually-beneficial strategic partnerships where buyers and suppliers win together and are invested in each other’s success. In today’s unpredictable landscape, there’s no better line of defense against risk than collaborative supplier relationships.

Explore how an SRM system can improve your Supplier Collaboration.

A New Era of Supplier Relationships

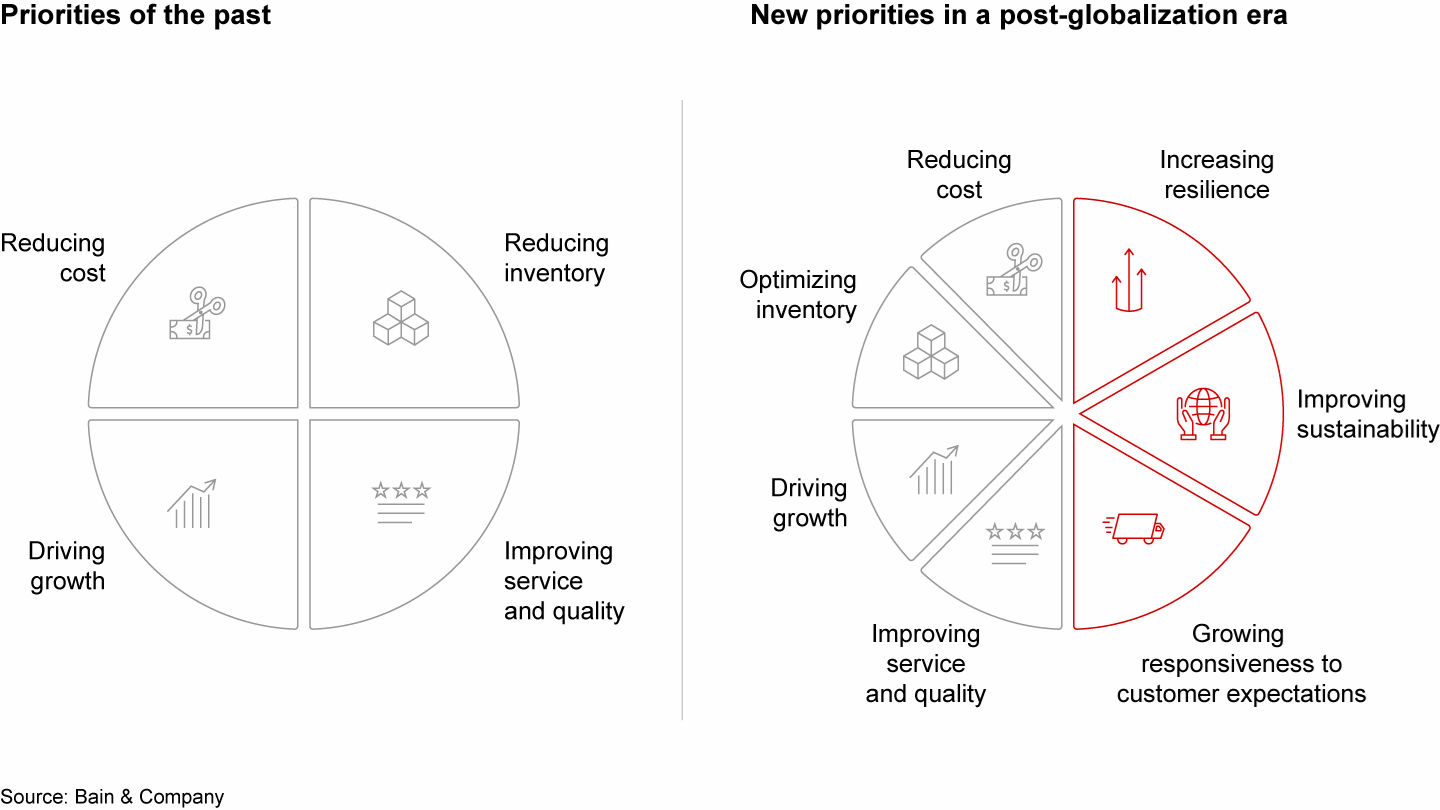

As these turbulent times force businesses to reimagine their supply chains and sourcing strategies, it’s important to remember that challenges can be the catalyst for positive change. Like the old saying goes: “Never let a good crisis go to waste.” And now that supply chain innovation has been elevated to a CEO-level problem and opportunity in many organizations, Procurement, Sourcing, and Supply Chain teams have the unique opportunity to turn these new challenges into long-lasting transformation that reimagines their role and drives sustainable value.

While there are many new strategies and technologies that Procurement can leverage to navigate this new era of risk and enhance supply chain resilience, smart Supplier Relationship Management should be at the core of any strategy. As Dr. Elouise Epstein wrote in this year’s ProcureTech 100 Yearbook, “The greatest risk to the enterprise comes from our supply base. The greatest opportunity to meet ESG compliance comes from our supply base. The best way to protect margin is through smart supplier management. We are not going to meet these challenges and opportunities through policies and processes.”

This new era of risk and resilience may be forcing businesses to reevaluate 30+ years of global supply chain practices, but it can also usher in a new era of relationships that unlock value and redefine global trade for decades to come…