Globalization has dominated as a widely practiced business strategy during the past 15–20 years.

Enter COVID-19, stage left, and the world as we know it has suddenly shrunken.

As the Coronavirus’ outbreak continues, and it’s residual effects upon the global economic state have only just begun, there are a lot of questions swirling around about the future of global business, and future application of globalization strategies.

One thing we can hypothesize with a good bit of confidence… global supply chains will likely not operate in a post-COVID-19 world as they did in a pre-COVID-19 world.

Managing a global supply chain in the current global business environment is a Tom Cruise-esque, Missions Impossible, kind of task. Many supply chain, sourcing & procurement teams have been asked to row upstream without a paddle during this time of crisis. Global supply chains are slowly being repaired, but many remain reliant upon interconnectivity, collaboration, and dependency across borders. Supply chains that are dependent upon a well-oiled globalized operation may be feeling like a sick and twisted Rube Goldberg experiment, at the moment.

This raises the question…

Is COVID-19 the beginning to the end of Global Supply Chains?

Globalization, Internationalization, & Localization

Many trusted sources accredit global GDP growth during the last 15–20 years, widely to the spread of globalization. “Globalization and increased economic interdependence have accompanied — and facilitated — rapid economic growth in many countries and regions, helping world GDP grow from around 50 trillion USD in 2000 to 75 trillion USD in 2016” (un.org 2017).

But what is globalization, really? And, how do localization & internationalization play a role in organizations that have succeeded ‘going global’?

Globalization: Globalization is the act of ‘going global’, meaning expanding your business beyond domestic borders. Within a business context, “It includes the processes through which you learn about both international law and local regulations, how to build a multinational business environment, and connect with international partners to increase your chances of success” (Phrase 2020).

Internationalization: “Internationalization is a corporate strategy that involves making products and services as adaptable as possible, so they can easily enter different national markets” (Lionbridge 2020). This typically involves adjustments in the go-to-market that greatly impact marketing and sales activities such as translation, messaging, repackaging, etc.

Localization: Localization is the act of adapting a product or service to local markets. In terms of supply chain management, the term can be used to describe domestic sourcing, production, and distribution of a good or service.

Localization & Internationalization are necessary to truly achieve globalization, as ‘going global’ still requires a focus on penetrating individual local markets. It’s important to also note that just because an organization practices localization, doesn’t mean that they can’t maintain a global presence, and vice versa.

Understanding how globalization, internationalization & localization are intertwined, can be best explained by using a truly global organization, as our reference point.

EXAMPLE: The Golden Arches, AKA McDonald’s.

“McDonald’s operates over 30,000 restaurants in 100 countries. Its worldwide expansion is an example of globalization. By design, the corporation creates a menu adaptable to various local tastes and customs. This policy is an example of internationalization” (Lionbridge 2020).

In the Israeli market, McDonald’s serves kosher alternatives, and more vegetarian menu items in certain restaurants in India, exemplifying localization of their products. All the while, McDonald’s retained its global approach, brand, image, operations & supply chain (Guardian 2006).

Download the Free : 15 Do’s and Don’ts for your Procurement Team

Will COVID-19 Create More Local Supply Chains?

McDonald’s is a perfect example of a global organization that will certainly feel residual effects of COVID-19’s impact upon consumer habits during country lockdowns, declining consumer trends & inability to open 100% of brick and mortar locations.

With that being said, McDonald’s supply chain has likely been able to stabilize quicker than others during this pandemic as their immensely global organization provides access to a massive global supply network, where alternative supply sources can be located and there’s often less key supplier dependency or local ownership to the sourcing process. An organization with McDonald’s global footprint is likely able to apply global agile procurement frameworks, and solve supply-demand challenges more effectively during abnormal circumstances.

About a month ago, in late April 2020, McDonald’s in Canada was experiencing a shortage of local beef supplies and therefore needed to access global alternatives. “McDonald’s cited the temporary closure of Cargill’s High River, Alberta facility, and said it was working with the meat processor and other global suppliers to meet demand” (Reuters 2020).

Their global presence allowed the organization to pivot in a time of crisis, and activate alternative supply sources.

At the same time, a global supply chain comes w/ global challenges. Risk & resilience is more difficult to manage as the supplier base/tail-end often grows, and supply chain mapping becomes very complex, if not impossible. Lacking supplier management and insights into the tiers of one’s supply chain can be detrimental to an organization during times of uncertainty and change, where the stability of key suppliers becomes crucial.

So… is there value in thinking more local, and stepping away from global supply chains? Or, do the benefits of a global supply chain greatly outweigh the risks?

Again, creating a more localized supply chain and local sourcing operation doesn’t necessarily cancel out the ability to retain a global footprint, and continue to reap the benefits of a global supply chain network. But, it does require a shift in mentality, organizational structuring, centralized leadership, and added local talent/competence development.

Localizing your supply chain efforts could be perceived as siloing, within particular countries, or business units. That’s why locally-driven supply chain organizations are still best led by a central, or global-level leadership.

Some benefits of localized supply chains can be as follows:

- Improved PR — Growing/supporting local economies & workforces

- Go-to-Market Speed & Agility

- Closer Vendor/Supplier Collaboration

- Better Buyer Control

- More Accurate Forecasting for Supply & Budget

- Not just Buyers & Suppliers, but Partners

- Ability to manage Ethical Integrity (Fogle 2018)

In a post-COVID-19 world, it may become more attractive to go ‘local’, and aim to source, produce, package, and sell in the same local, domestic, or — at least — continental markets. But, is it even possible in 2020 to localize supply chain operations, and remain competitive in industry verticals where cheap foreign labor, production & raw material sources are so prevalent?

Have We Really Gone Global, Yet?

Though we live in a very ‘global’ world, the fact is that many professional purchasers already buy incredibly local.

According to a 2019 B2B buyer survey, about 72% percent of buyers responded that they always or generally prefer to source locally. In comparison, just 10.8% of respondents “always, or generally” prefer to source globally, and nearly half of buyers who responded (46.7%) stated they “rarely or never” prefer to source globally (Thomasnet.com 2019).

The global supply chain may not be all that global after all, but — in fact — greatly dependent upon individual local operations, that collectively make up a global supply network.

This speaks directly to our human/buying psychology. We like to invest in what we know. Things in our country, things in our language, and local supply chains are often familiar/comfortable.

Globalization, while accredited as a key factor for the past 20 years global GDP growth, may not be quite as prevalent as we believe. Don’t believe me? That’s probably because you’ve been subject to the globalization of information, just like the rest of us! But, has the globalization of trade, capital & people seen the same exponential growth?

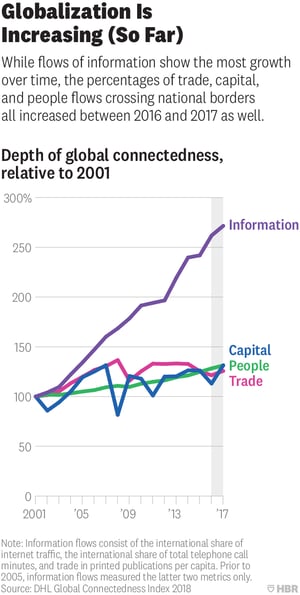

Looking at the graphic below from HBR’s 2019 article, it’s apparent that information is more abundant within global networks than ever before, and growing.

“With globalization’s strong momentum running up against powerful headwinds, it is important to recognize that market integration is still limited in absolute terms. The foreign operations of multinational firms around the world generate only about 9% of global output. Exports of goods and services add up to 29% of world GDP, but even that figure comes down to about 20% if we adjust for output that crosses borders more than once. Surprised? You’re in good company. Managers we surveyed across six countries in 2017 estimated these international production and trade metrics at 37% and 41%, respectively.

This striking juxtaposition of global flows running close to all-time highs but still falling far below managers’ perceptions highlights both the opportunities and the challenges that globalization continues to pose for multinational firms. Succeeding across borders and distances is still much more difficult than winning at home, but some of the same barriers that constrain international flows also increase the rewards for companies that find ways to overcome them” (HBR.org 2019).

So, the question remains…

Will COVID-19 create a Death of Global Supply Chains and a rebirth of Local Supply Chains? Or, have we just begun ‘Going Global’?

It’s your turn to decide.