5 Ways Procurement Can Buy Smarter With Supplier Ratings

1. Owning KPIs & Targets

Building a solid foundation and framework for insightful supplier rating requires the definition and implementation of three main rating cornerstones:

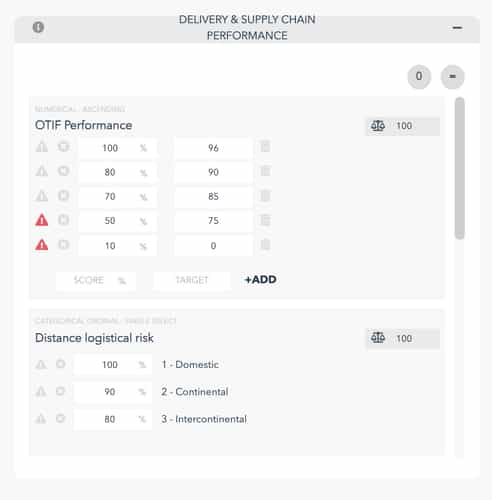

- Key Performance Indicators (KPIs): What criteria/parameters do you want to measure & rate in your supplier rating?

- Goal/Targets: What is the desired output of suppliers?

- Acceptance Criteria: What is the minimum & maximum output to be accepted?

KPIs will vary depending on the industry, size of the company, size of supplier, category, type of supplier, etc. With this said, delivery and cost shouldn’t be the only dimensions you’re measuring suppliers against (you should of course be measuring these as well 😊).

Building a diverse and holistic criterion for supplier KPIs will diversify and strengthen the reliability of supplier ratings. Defining KPIs will also aid you & your procurement team in determining what/where data/information inputs should be collected in order to best generate supplier ratings.

Setting Goals and/or Targets on Supplier KPIs is a great exercise to align your procurement team internally and align to broader business objectives. This is also a great way to make goals measurable throughout the buyer-supplier relationship, which can lead to cross-functional benefits impacting sustainability, quality, supply chain, and more. Target configuration should start simply by using a 0–10 or 0–100 scale, and apply Yes/No, Multi-select, and/or Multiple-Choice data entry on KPIs in order to best-set goals, weight data inputs, and set acceptance criteria that fits the KPI you’d like to rate.

Multiple-choice survey/questionnaire methodology may seem outdated, but it’s only outdated if you’re relying upon your excel spreadsheets to complete surveys. Modern solutions (including Kodiak Hub) show that this methodology is still an incredibly useful and powerful tool when data gathering is optimized, via API inputs and streamlined stakeholder reporting, so you spend less time configuring your spreadsheet, and more time analyzing supplier ratings.

2. Buyer-Supplier Alignment & Engagement

Supplier Ratings provide a framework for accountability, trust, and transparency in buyer-supplier relationships.

Rating can make buyer-supplier relationship management more objective, and feedback, corrective actions, or improved proposals to suppliers can be established in holistic data intelligence, rather than a gut-feeling. Again, it’s important to not leave your head (or gut-feeling) at home, but supplier ratings + human/emotional intelligence provide a balanced starting point for more meaningful and engaging supplier partnerships.

Having a supplier rating framework, process, and system in place allows you as a procurement professional to objectively communicate to your suppliers “This is what good looks like when collaborating with us”. This is a powerful tool for aligning expectations and service levels from the jump.

3. Balanced Scorecards For a 360º View

At Kodiak Hub our SRM solution has a strong focus on aiding procurement teams to build 360º supplier ratings, but more importantly to visualize supplier ratings in Balanced Supplier Scorecards.

It was reported in the 2021 Deloitte CPO Survey that high-performing procurement teams follow up on a wider array of supplier KPIs, including quality, sustainability, risk, innovation, and performance (Deloitte CPO Survey 2021). This is just one aspect of how the elite separates themselves from the rest of the pack, but it provides a great glimpse into the importance of measuring and following up on supplier KPIs. Having balanced supplier scorecards w/ balanced supplier ratings allows your procurement team to measure & follow up on a wider range of KPIs, faster.

Referencing back to the ‘traffic signal’-like insights Supplier Ratings provide, (Stop & Investigate, Proceed w/ Caution, Go for it) it’s important that your procurement team has an array of ‘traffic signals’ to check suppliers against a wide array of performance indicators.

At Kodiak Hub we aid teams to build balanced scorecards from an array of data sources in a wide range of supplier evaluation criteria. Our solution balances supplier ratings, by providing users with supplier ratings from (but not limited to):

- 3rd party data sources: Covering social, environmental, financial, media, and sanction-related risks.

- Company-Specific KPI definition: social, environmental, quality, IT, financial, supply chain, industry-specific compliance.

- Company-Specific KPI definition: quality, commercial, delivery, innovation, collaboration, and sustainability performance.

Balanced supplier ratings can help you and your team to buy smarter, but also safer and more sustainably.

4. Supplier Segmentation

Knowing who and where your best suppliers are can be complicated.

Segmenting, or classifying your supplier base can be a difficult task. There are a lot of models out there for supplier segmentation, with the Kraljic Matrix serving as one of the most common segmentation models.

If you find segmentation to be difficult, or time-consuming, supplier ratings can aid you in more quickly understanding suppliers that belong to different segments based upon a wide range of supplier rating criteria, as listed in the last point.

One could also reverse engineer supplier rating in order to build framework, process, and ultimately solution by starting with the desired segmentation model and working backward. Identifying the important segmentation personifications could help to quickly build criteria suppliers should be evaluated upon.

5. Sustainability & Governance at Scale

Putting a supplier rating methodology into place will compel your procurement team to define goals, measure progress, and report.

Rating suppliers provide a great means to objectively set goals and report. For this reason, rating suppliers poses a great opportunity to gain deeper buying insights and for procurement to show their worth cross-functionally in the organization.

Following up on an objective array of supplier KPIs in a systematic manner can support sustainability, risk, compliance, and quality teams to progress on ambitious business goals within supply chain transparency and sustainable development. Supplier Rating criteria (KPIs, Goals, and Acceptance Criteria) can also be tied back to ISO standards, UN SDGoals, EU taxonomy, and other international/domestic standard frameworks built to ensure that CSR & corporate ESG initiatives drive real change.

Supplier ratings provide your procurement team with a means to communicate best practices to suppliers, build an evaluation framework upon objectivity/fairness, and make more responsible sourcing/procurement decisions based upon a wider range of evaluation criteria. All the while, supplier ratings give you a means to better safeguard brand value, locate innovative partners and drive overall supply chain performance.

Are you ready to rate suppliers?